Bromer Inc X-Seamer: Best-in-Class Edge Seaming Solution

The Bromer Inc X-Seamer is a high-performance double sanding belt machine designed to streamline the edge seaming process on flat glass panels. Using two angled sanding belts (4” x 106”), it removes both the top and bottom edges of the glass in a single pass, significantly reducing handling time and minimizing injury risks.

By preparing the edges before tempering, the X-Seamer helps prevent glass breakage in the furnace—a critical step in ensuring the integrity of the tempered glass.

Superior Design and Build Quality

-

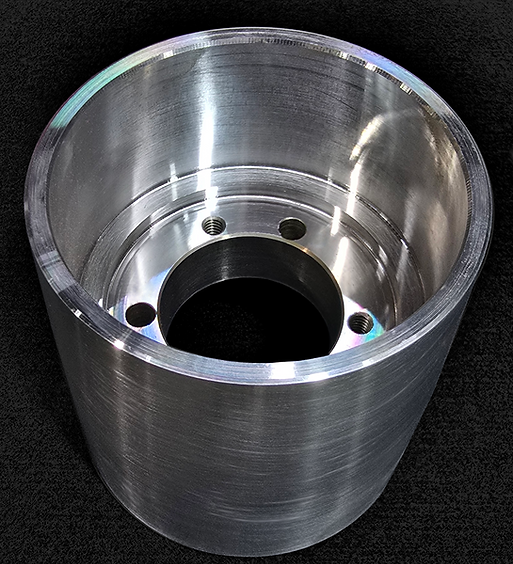

Heavy-Duty Aluminum Construction: Built with the thickest aluminum frame in its class, the X-Seamer delivers unmatched durability and stability.

-

Longevity of Components: Every part is engineered for long service life, minimizing downtime and maximizing return on investment.

-

Easy Maintenance: Spare parts are fast and easy to obtain, ensuring your operation stays running smoothly with minimal delays.

Wet Seaming Compatibility

The X-Seamer can be equipped with a wet seaming package that includes:

-

Water-resistant motor

-

IP63-rated electrical starter

-

Precision water injector

-

Solenoid valve with automated control

-

Garden hose adapter for fast connection

-

Fully sealed base for water protection

-

Integrated water tray to manage water flow and containment

This configuration ensures excellent cooling and dust suppression during high-throughput operations.

Dry Seaming vs Wet Seaming Dry Seaming No need for glass washing after seaming Dust is easily collected using a specialized dust collection system Longer lifespan for bearings and caster wheels, as components are not exposed to water and abrasive glass slurry Ideal for operations prioritizing cleanliness and low-maintenance Wet Seaming Faster process due to improved cooling and reduced clogging Extends sanding belt lifespan, lowering replacement frequency Smoother edge finish, reducing risk of chipping or post-processing issues Highly effective for high-throughput or delicate glass applications

Frequently Asked Questions – Glass Transportation Systems

What types of vehicles can be equipped with a Bromer glass rack?

Bromer glass rack systems are designed for a wide range of commercial vehicles, including pickup trucks, vans, cube vans, cab-over trucks, medium-duty trucks (Class 5–7), trailers, and semi-trailers. Each system can be adapted to the specific vehicle configuration and job requirements.

Are Bromer glass racks custom-built or standard products?

Bromer offers both standardized models and fully customizable glass rack systems. Our modular design allows each rack to be configured with specific dimensions, options, and accessories to match real job site conditions.

What materials are used in Bromer glass rack systems?

All Bromer glass racks are manufactured using high-quality aluminum. This ensures an optimal balance between strength, durability, corrosion resistance, and weight reduction for commercial applications.

Do Bromer glass racks require drilling into the vehicle?

Most Bromer glass rack systems are designed to be installed without drilling into the vehicle structure. This helps preserve vehicle integrity while allowing secure and stable load support.

Can Bromer glass racks transport long or oversized glass panels?

Yes. Bromer offers multiple solutions for transporting long or oversized glass panels, including over-cab extensions, goal post systems, rear section extensions, and enclosed configurations designed specifically for extended loads.

Are Bromer glass racks suitable for fleet operations?

Absolutely. Bromer glass rack systems are widely used by fleet operators due to their durability, modularity, and long service life. Fleet configurations can be standardized across multiple vehicles while remaining adaptable to specific operational needs.

How are glass loads secured during transport?

Glass loads are secured using Bromer’s patented pole system, reinforced contact surfaces, ledgeboards, and optional locking or strap systems. Each configuration is designed to maintain load stability during transport, braking, and cornering.

Can interior and exterior glass racks be combined on the same vehicle?

Yes. Many Bromer systems combine exterior glass racks with interior racks to increase load capacity while maintaining organized and safe material transport.

Are Bromer glass racks compatible with enclosed bodies and fiber caps?

Yes. Bromer offers solutions for enclosed bodies, fiber caps, SpaceKap systems, and trailers, with dedicated mounting methods to ensure proper load support and structural integrity.

How do I choose the right glass rack configuration for my vehicle?

Choosing the right glass rack depends on vehicle type, load size, frequency of transport, and job site conditions. Bromer’s team works closely with customers to recommend the most efficient configuration based on real operational needs.