Glass Storage Equipment

Maximize Your Space. Boost Your Efficiency. Increase Your Profitability.

Bromer’s glass storage rack solutions provide organized, high-density storage for glass packs, glass crates, and related materials in warehouse, shop, or production environments.

Our storage racks are engineered for industrial handling, optimized for safe access, material protection, and efficient workflows.

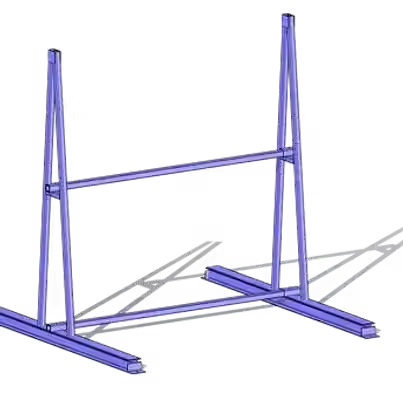

Multiple configurations are available, including fixed A-frame, L-frame, free-fall, and heavy-duty systems, to support a wide range of sizes, formats, and handling requirements.

Each system can be customized in layout, load capacity, and finish to fit your facility and workflow needs.

Storage rack

Storage solution

Bromer designs and manufactures a complete range of warehouse storage racks for glass packs, glass crates, and stone materials.

Our storage rack systems are engineered to provide safe load support, organized storage, and efficient access in warehouse and production environments. Multiple configurations are available to match your material formats, handling methods, and space constraints.

From rail and pole systems to A-frame and L-frame designs, Bromer storage racks are built for durability, stability, and long-term industrial use.

Each solution can be customized in size, load capacity, and layout to integrate seamlessly with your operation.

Frequently Asked Questions – Glass Storage Equipment

Are Bromer’s glass storage systems custom engineered?

Yes. All Bromer glass storage solutions are custom-designed to fit your facility’s space, workflow, load requirements, and traffic patterns. We don’t use one-size-fits-all designs.

What types of glass can be stored with your systems?

Our storage equipment supports a wide range of glass products, including tempered, laminated, insulated units (IGUs), large architectural panels, and specialty glass sizes.

Can your storage systems integrate with existing handling or transportation equipment?

Absolutely. Bromer storage solutions can be designed to interface with your existing handling, racking, conveyor, or transport systems when required.

What information do you need to start a storage equipment quote?

Typical details we request include:

-

Glass dimensions / formats

-

Expected storage capacities

-

Facility layout and aisle clearances

-

Handling process upstream/downstream

This information allows us to engineer the safest and most efficient storage configuration.

Do you offer solutions for both shop and field storage?

Yes. We design storage systems for indoor use (manufacturing and staging) as well as configurations suitable for field storage when required (weather protection, mobile units, etc.).

Are your storage systems designed with safety in mind?

Yes. Bromer’s glass storage equipment is engineered for industrial use, with enhanced safety features, stable load support, and compliance with ergonomic and workplace safety expectations.